Standard parts

Blades serious

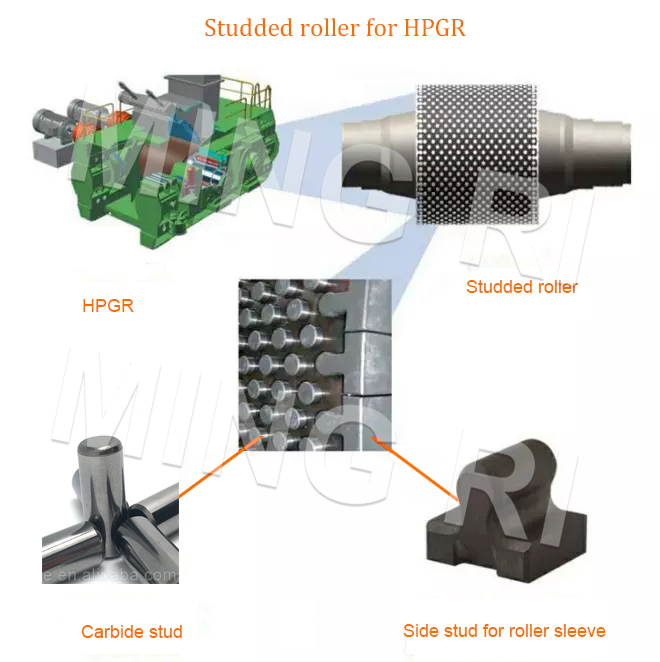

Grinding Copper Ore for Weir′s Machine Tungsten Carbide Hpgr Studs

Grinding Copper Ore Used In Weir's Machine Tungsten Carbide HPGR Studs

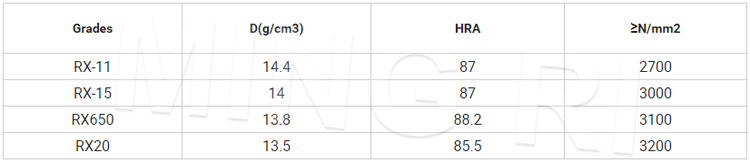

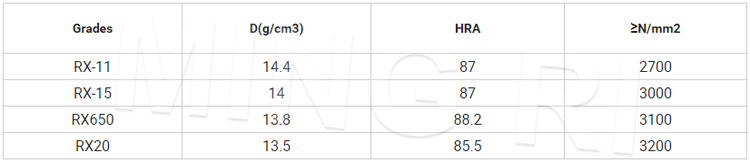

Description of carbide HPGR studs

Grades above are exclusive grade we developed for rolling machine. Good wear resistance and high strength are suitable for metal smashing with high working efficiency. Lifetime of carbide stud is over 8000-10000 hrs.

Dimensions can be done by client's drawing.

1. Flat top, protect the studs from being destroyed by stress concentration.

2. Round edges, protect the stubs being damaged during production, transportation, installment and using.

3. HIP sintering ensure good compactness and high toughness for the products.

4. Special technology to eliminate the surface stress after surface grinding, and increase the surface hardness at the same time.

5. Grease used on surface of the products to avoid oxidization.

unit MM

If rolling machine uses cemented carbide stud, it gets high density,high strength and good impacting property. Lifetime of Cemented carbide stud is over 10 times more than surfacing material.

Production process of carbide HPGR studs

1, Soon after the order is confirmed, Tungsten HPGR Studs products will start to prepare the RTP powder as per customer's requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of Tungsten HPGR Studs samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all Tungsten HPGR Studs blanks must be passed by semi finished inspection,

4, Then sinter blanks to finish (HIP) and finished products inspection, we have 10 sets of vacuum sintering furnace and 2 sets of HIP in the factory ensure the best quality and production capacity.

5, 1). cleaning/tumbling is to make the Tungsten HPGR Studs look more beautiful.

2).The Tungsten HPGR Studs can be ground according to customers' order tolerance requirement

Packing and shipping of carbide HPGR studs

step 1, wrapped Tungsten HPGR Studs in paper to avoid Tungsten HPGR Studs to broke

step 2, put the Tungsten HPGR Studs in inner small carton box

step 3, put the inner box into outter carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

step 5, you can choose any delivery way such as DHL,TNT,UPS ect

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn