Standard parts

Blades serious

Hot selling tungsten carbide button bit/indexable inserts/braze tips

Grades of Hot selling tungsten carbide button bit/indexable inserts/braze tips

| Grade | Density | T.R.S | Hardness | Performance & application recommended |

Approx Grades in China |

| g/cm3 | MPα | HRA | |||

| MK4 | 15.1 | 1800 | 90 | Mainly used as small buttons for percussion bits to cut soft and medium hard formations. | YG4C |

| MK6 | 14.9 | 2100 | 90 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. |

YG6 |

| MK6 | 14.7 | 2400 | 89.5 |

For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

YG8 |

| MK15 | 14 | 2500 | 87.5 |

Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. |

YG15 |

| MK10 | 14.7 | 2450 | 88.5 |

Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

YG8C |

| MK15 | 14.7 | 2450 | 87.8 |

Suitable to strips, conical buttons for rotary,percussion-resistant, geological prospecting,buttons, cut soft and medium hard formations. |

YK15/YG9C |

| MK20 | 14.4 | 2550 | 87 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

YG20/YG10C |

| MK25 | 14.5 | 2600 | 87.5 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium hard and very hard formations. |

YK25 |

| MK30 | 14.4 | 2600 | 87 |

Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

YG11C |

| MK40 | 14.2 | 2650 | 86.5 |

Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. |

YK40/YG13C |

| MK50 | 14 | 2700 | 86.5 | For oil cone drill bits, for medium soft and medium -hard rocks. | YG15C |

Other grades may be offered by customers' requirements.

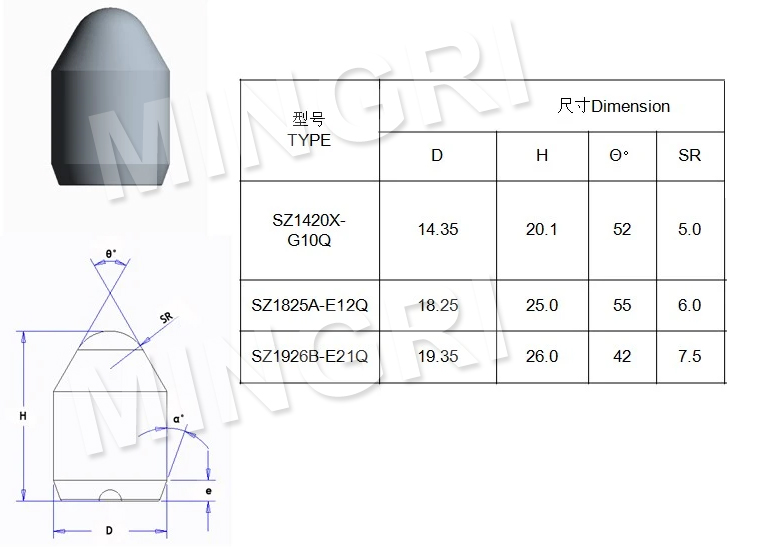

Drawing of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

Application of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

Carbide button teeth normally used for

Grinding cement clinker,

Grinding cement limestone

Grinding cement bauxite, iron ore, etc

Production Process of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer's requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

Test process of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

1st,Mass production, press the raw materials to shape blanks,

Notes: all carbide button blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2 set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide button clean and nice surface.

Packing of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

step 1, wrapped carbide button tips in paper to avoid carbide button tips be broken

step 2, put the carbide button tips in inner small carton box

step 3, put the inner box into outer carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn