Standard parts

Blades serious

Tungsten Carbide Button Tips for Mining

Grade of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

Mainly used as small buttons for percussion bits to cut soft and medium hard formations, small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations.

| Grade |

Density g/cm3 |

Hardness HRA |

T.R.S MP a |

Performance & application recommended | Approx Grades in China | ISO |

|

MK4 |

15.1 |

90.0 |

1800 |

Mainly used as a small buttons for percussion bits to cut soft and medium hard formations |

YG4C |

K01-K05 |

|

MK10 |

14.7 |

89.0 |

2700 |

Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary of prospecting bits to cut soft and medium hard formation. |

YG8C ZD15 |

K20 |

|

MK15 |

14.6 |

88.0 |

2750 |

Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations. |

YK15 YG9C |

K20-K30 |

|

MK20 |

14.5 |

87.5 |

2800 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

YK20 YG10C |

K30 |

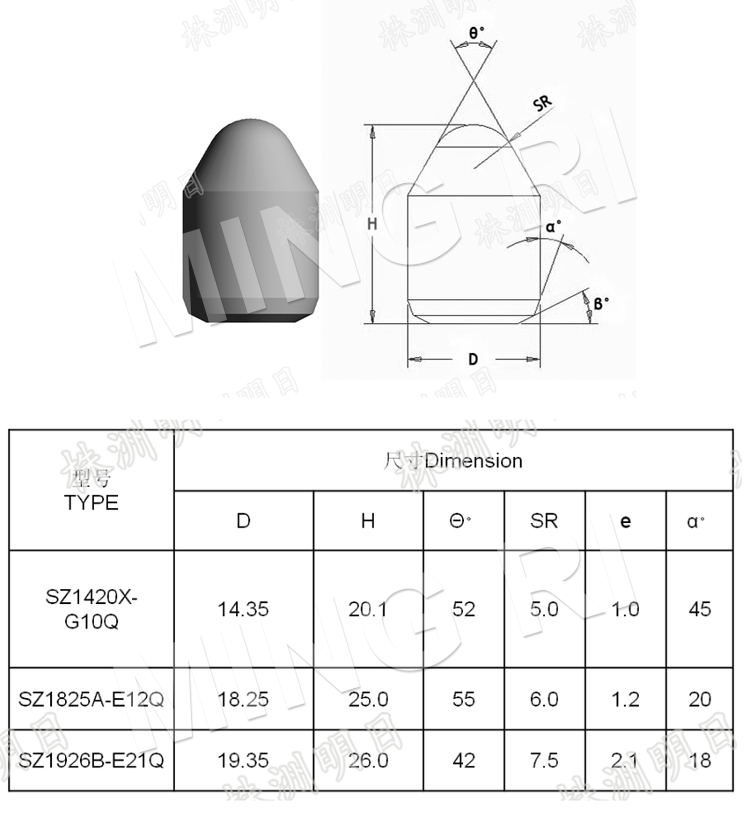

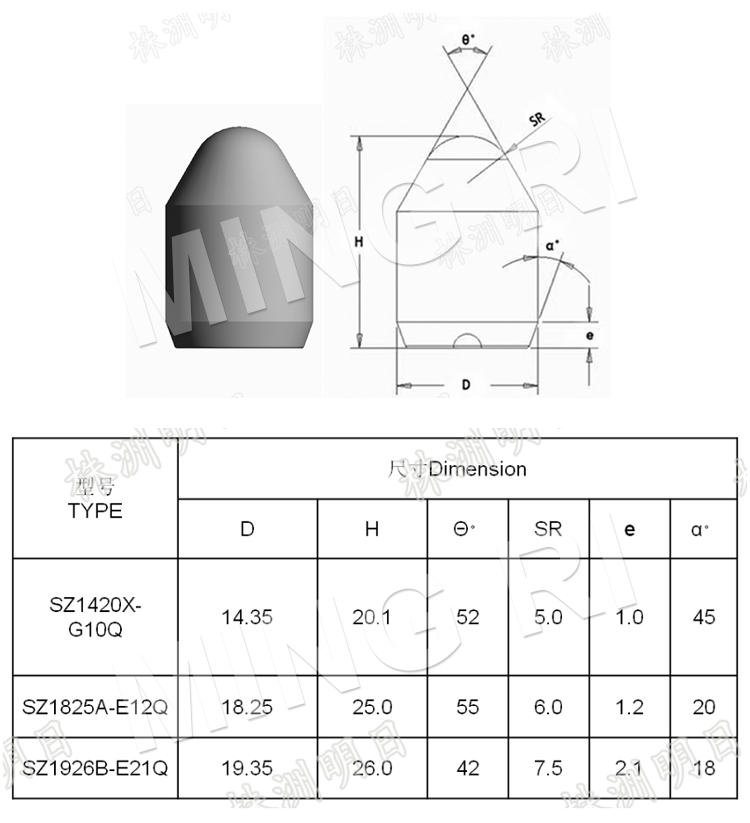

Drawing of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

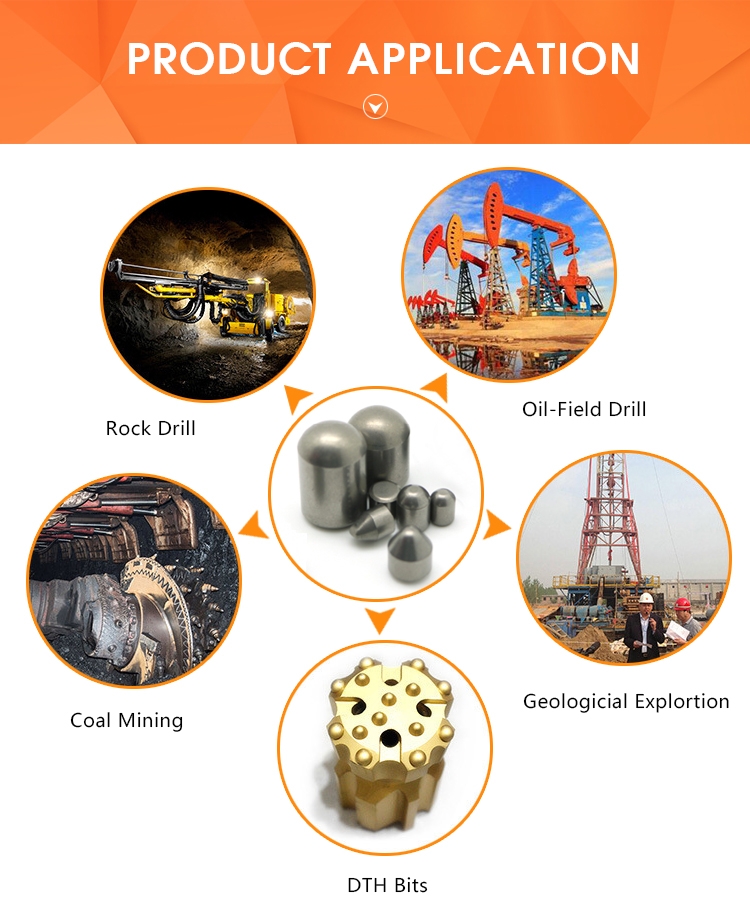

Application of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

Carbide button teeth normally used for

Grinding cement clinker,

Grinding cement limestone

Grinding cement bauxite, iron ore, etc

Related products of Oil-Field Drill Bits Polished Cemented Tungsten Carbide Button Teeth Tips

Our related products cover cold heading dies, wire drawing dies, strips and plates, saw tips, brazed tips, disc cutters, round rods, rock drilling bits and buttons, milling tools, also we can make all kinds of customized proposal to meet customers' requirement.

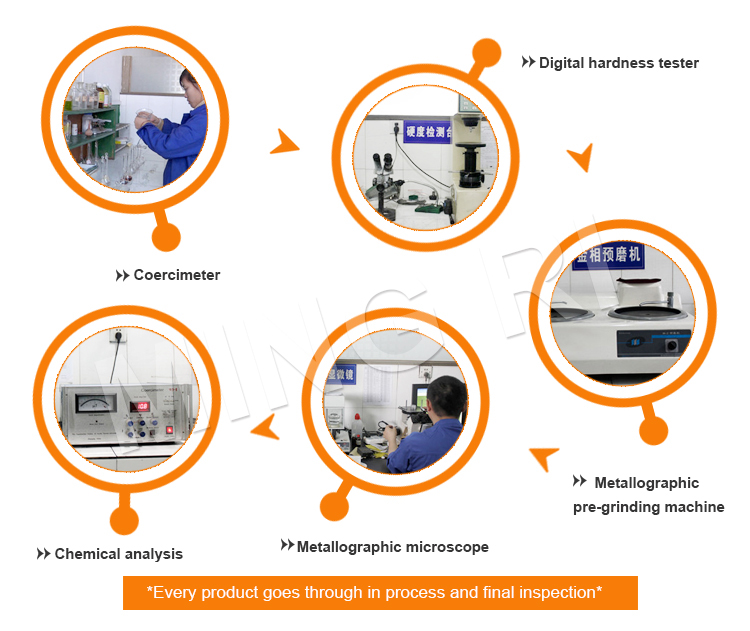

1, Soon after the order is confirmed,tungsten carbide plate products will start to prepare the RTP powder as per customer's requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of tungsten carbide plate samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all tungsten carbide plate blanks must be passed by semi finished inspection

4, Then sinter blanks to finish (HIP) and finished tungsten carbide plate inspection, we have 10 sets of vacuum sintering furnace and 2 setz of HIP in the factory ensure the best quality and production capacity.

5, 1). cleaning/tumbling is to make the tungsten carbide plate look more beautiful.

2).The tungsten carbide plate can be ground according to customers' order tolerance requirement

Trade show

Zhuzhou Mingri Cemented Carbide Co.,Ltd is opening new and bigger market, we have many good show as below:

1,We did some Trade Assurance order on alibaba, keep customer can get good quality products and efficient delivery time.

2, Mingri overseas team attend many different country fair show each year, like Germany, Russia, Brazil, Australia, India, etc, and got good feedback for the High density hard alloy wear resistant cemented tungsten carbide plates

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn