Standard parts

Blades serious

Carbide Strips for Conveyor Belt Cleaning in The Mining Sector

Recommend grade list of tungsten carbide strips and plates:

| Grade | Density g/cm3 | Hardnes HRA | T.R.S Mpa | Performance&application recommended |

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,wear-resistant parts etc. |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG11 | 14.4 | 88.5 | 2900 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG15 | 14.0 | 87.0 | 3000 | Suitable for manufacturing punching dies, wear-resistant parts. |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength,suitable for manufacturing progressive dies and other punching dies. |

| YG25 | 13.1 | 81.5 | 2950 | High bending strength,wear resistance lower than YM6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YS2T | 14.25 | 92.0 | 2500 | Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. it is suitable for machining refractory alloys,stainless steel, high manganese steel, etc. |

Product size reference:

| Type (L×W ) | Thickness (H) | Tolerance | ||

| Length (L) | Width (W) | Height (H) | ||

| 50×50× | 1.5~10 | L×±1.5% | W×±2.5% | H×±2.5% |

| 100×100× | 2.5~60 | |||

| 120×120× | ||||

| 150×150× | ||||

| 200×200× | ||||

| 300×200× | ||||

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer's requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

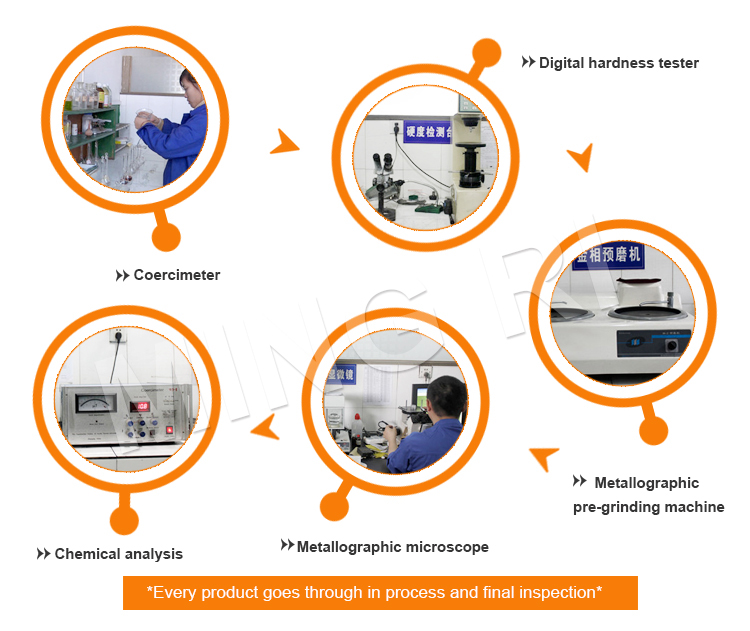

Test process of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

1st,Mass production, press the raw materials to shape blanks,

Notes: all carbide stud pins blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide stud pins clean and nice surface.

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn