Standard parts

Blades serious

Tungsten Carbide Cold Heading Die

Tungsten Carbide Cold Heading Die

With High wear resistance and good impact toughness,made of 100% virgin cemented carbide raw materials,The Tungsten Carbide Cold Heading Stamping Dies are used for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc.The non-standard sizes of tungsten carbide dies can also be produced as per customer requests.

Grades of tungsten carbide dies

|

Grade |

Density g/cm3 |

Hardness HRA |

T.R.S Mpα |

Performance&application recommended |

|

YG11 |

14.4 |

88.5 |

2420 |

Forming or stamping dies for metal powders and nonmetal powders |

|

YG15 |

14.0 |

87 |

3000 |

It is suitable for drawing steel tubes and rods under high compression ratio,manufacturing upsetting,punching and stamping tools under large stress |

|

YG20 |

13.5 |

85.5 |

2800 |

It is suitable for manufacturing punching dies for watch parts,leaf spring of musical instrument,battery jars,small sized steel balls,screws,screw caps,etc |

|

YG16C |

13.9 |

85 |

2750 |

It is suitable for impact-resistant forging dies |

|

YG18C |

13.7 |

84 |

2800 |

It is suitable for impact-resistant forging dies,hot-forging dies and finishing rollers |

|

YG20C |

13.5 |

83 |

2850 |

It is suitable for wear resistant or impact resistant dies |

|

YG22C |

13.3 |

82 |

2900 |

It is suitable for nut forming dies and high impact-resistant dies |

|

YG25C |

13.1 |

81.5 |

2950 |

It is suitable for stainless screw dies and semifinishing rollers |

|

Other grades and sizes can be offered as per customers' requirement |

||||

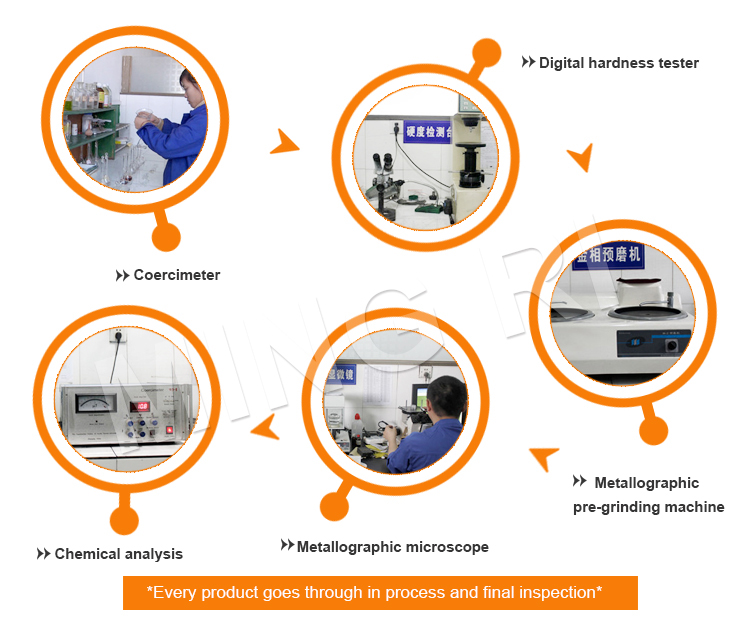

Production process of tungsten carbide die

1, Soon after the order is confirmed,tungsten carbide die products will start to prepare the RTP powder as per customer's requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of tungsten carbide die samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all tungsten carbide die blanks must be passed by semi finished inspection

4, Then sinter blanks to finish (HIP) and finished tungsten carbide die inspection, we have 10 sets of vacuum sintering furnace and 2 setz of HIP in the factory ensure the best quality and production capacity.

5, 1). cleaning/tumbling is to make the tungsten carbide die look more beautiful.

2).The tungsten carbide die can be ground according to customers' order tolerance requirement

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn