Standard parts

Blades serious

Hard Alloy Carbide Roller Press Hpgr Studs Pin for Crushing Iron Ore

Description of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

-100% virgin raw materials, stable chemical properties, long life circle.

-High hardness, good hardness, excellent wear-resistance.

-Various sizes and full types available

-Products can be customized upon requirement

Grade of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

Grades are exclusive grade we developed for rolling machine.

High impact toughness, high abrasion resistance, stable physical ability, the appearance of fine workman ship etc.

| Grade | Density g/cm3 | Hardness HRA | T.R.S MPa | Performance & application recommend | Approx grades in China | ISO |

| MK4 | 15.1 | 90.0 | 1800 | Mainly used as small buttons for percussion bits to cut soft and medium hard formations | YG4C | K01-K05 |

| MK6 | 14.9 | 90.5 | 2600 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring | YK05 KK06H | K10 |

| MK8 | 14.7 | 89.8 | 2800 | Suitable for coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring | YG8 | K20 |

| MK10 | 14.7 | 89.0 | 2700 | Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

YG18C ZD15 |

K20 |

| MK15 | 14.6 | 88.0 | 2750 | Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations |

YK15 YG9C |

K20-K30 |

| MK20 | 14.5 | 87.5 | 2800 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

YK20 YG10C |

K30 |

| Other grades and sizes can be offered as per customers' requirements | ||||||

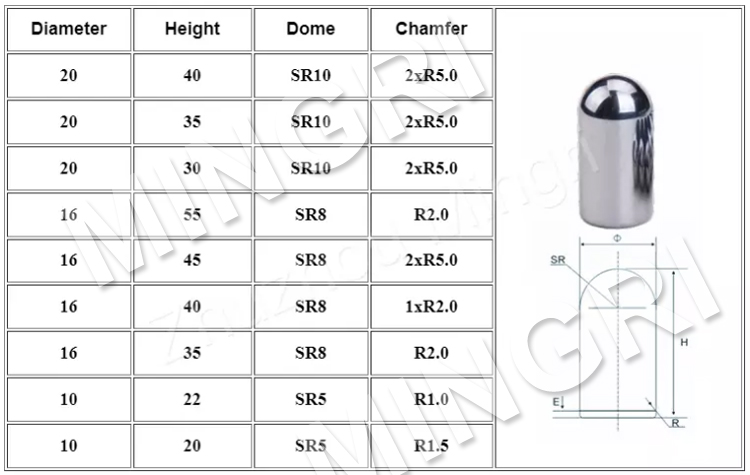

Drawing of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

It is with long life time carbide stud pins

This equipment can do the field operation that not affect any construction on the ground.

This is available and best choice for crowd city areas, protecting buildings or historic site on the ground.

Application of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

Carbide stud pins normally used for

Grinding cement clinker,

Grinding cement limestone

Grinding cement bauxite, iron ore, etc

Production Process of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer's requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

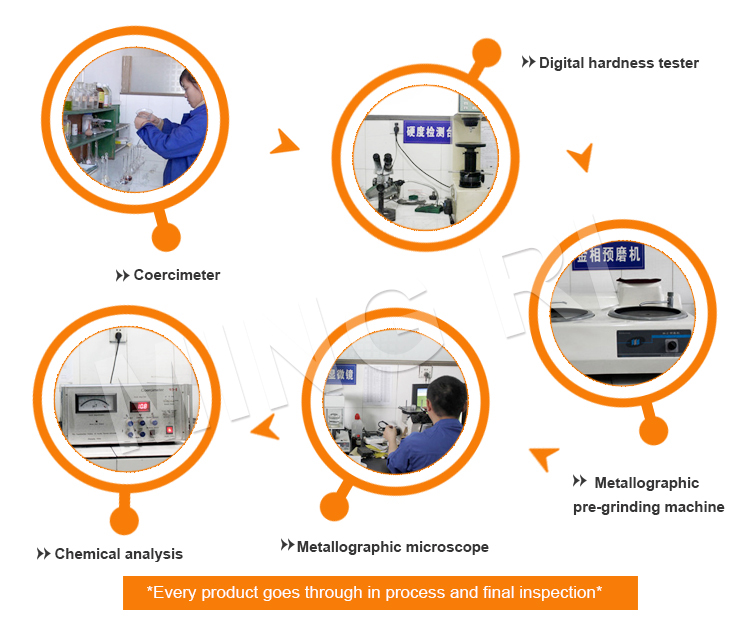

Test process of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

1st,Mass production, press the raw materials to shape blanks,

Notes: all carbide stud pins blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide stud pins clean and nice surface.

Packing of Hard Alloy Carbide Roller Press HPGR Studs Pin for Crushing Iron Ore

step 1, wrapped carbide stud pins in paper to avoid carbide stud pins be broken

step 2, put the carbide stud pins in inner small carton box

step 3, put the inner box into outer carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn