Standard parts

Blades serious

for Breaking Stones Cement Cemented Carbide Stud Pins for Hgpr

For breaking stones cement cemented carbide stud pins for hgpr

Product Features

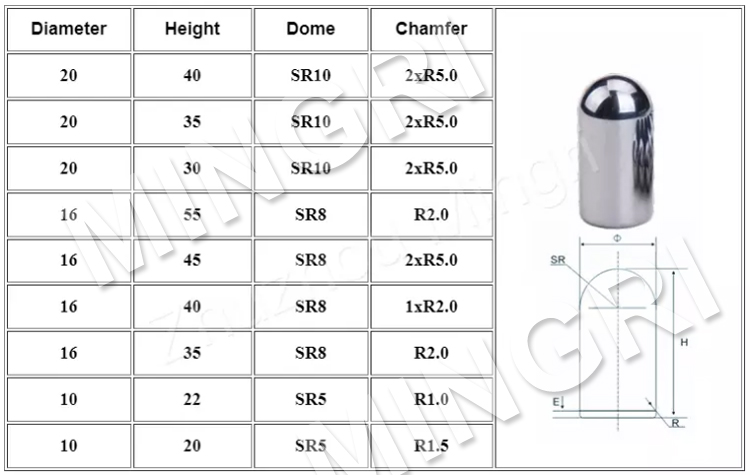

1) Spherical crown was made of hemisphere design, to avoid stress concentration cause to steel damaged.

2) Corner with arc transition, to avoid the damage during production, transportation, installation, and using procedure.

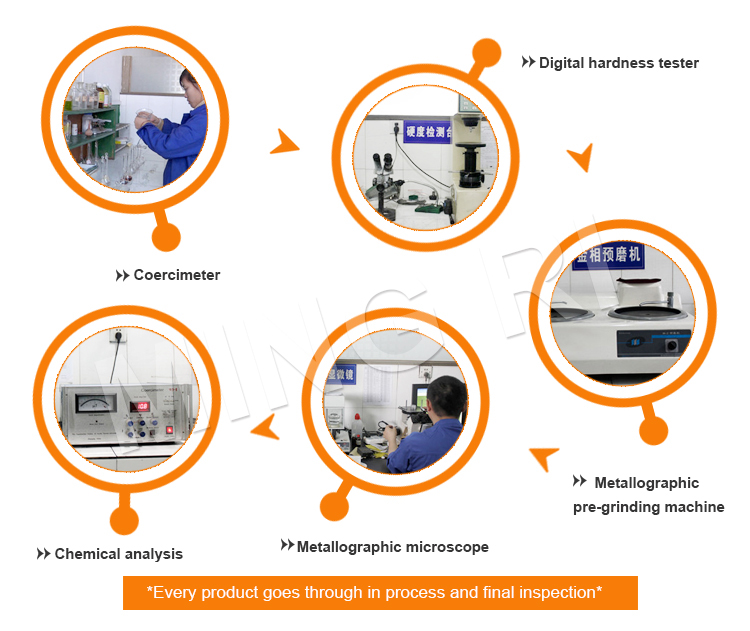

3) HIP sintered, good product density and high strength.

4) Apply special technology to relieve stress of product surface after processing, at the same time improved surface hardness.

5) Product surface coated with a layer of grease to avoid oxidation.

Application of For breaking stones cement cemented carbide stud pins for hgpr

High Pressure Grinding Roller is an energy-efficient crushing equipment of new technologies, widely used in grinding cement clinker,limestone,bauxite,iron ore.. High performance of carbide stud extends the life of High Pressure Grinding Roller. Zhuzhou Mingri provide quality carbide studs with good wear resistance and high compressive strength, can satisfy the requirements of different conditions.

Our Advantages:

1.Hemispherical top, protect the studs from being destroyed by stress concentration.

2.Round edges, protect the stubs being damaged during production, transportation, installment and using.

3.HIP sintering ensure good compactness and high toughness for the products.

4.Special technology to eliminate the surface stress after surface grinding, and increase the surface hardness at the same time.

5.Grease used on surface of the products to avoid oxidization.

Grades below are exclusive grades we developed for rolling machine. Good wear resistance and high strength are suitable for metal smashing with high working efficiency. Lifetime of carbide stud is over 8000-10000 hrs iron ore and 25000hrs for cement.

| Grade | Physical Properties | Chemical Composition(%) | ||||

|

Hardness (HRA) |

Bending Strength (>=N/mm²) |

Density (g/cm³) |

Coercivity (kA/m) |

Cobalt | Carbon | |

| YG15C | 85.0~86.5 | 2500 | 13.90~14.10 | 4.5~6.5 | 14.7~15.3 | 4.90~5.50 |

| YG20 | 86.0~87.5 | 2450 | 13.40~13.60 | 8.0~11.0 | 19.7~20.4 | 4.50~4.80 |

| YG15 | 87.0~88.5 | 2800 | 13.95~14.15 | 7.0~10.0 | 14.1~14.8 | 4.95~5.60 |

| RX650 | 87.8~90.0 | 2950 | 13.95~14.15 | 8.0~10.5 | 14.5~14.9 | ----- |

| RX20 | 85.8~87.2 | 2600 | 13.87~14.17 | 5.8~8.0 | 14.8~15.2 | ----- |

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn