Standard parts

Blades serious

Tungsten Carbide Tbm Shield Driving Cutters

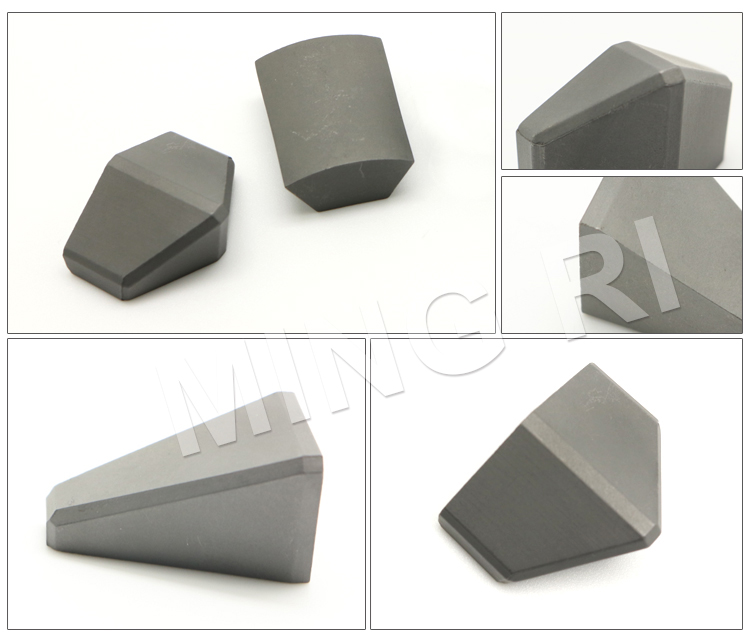

Description of hard alloy shield cutter teeth

hard alloy shield cutter teeth for Tunnel Boring Machinery Tool Part

-100% virgin raw materials, stable chemical properties, long life circle.

-High hardness, good hardness, excellent wear-resistance.

-High accuracy with long lifespan

-Hip sintered, good performance

-Various sizes and full types available

-Products can be customized upon requirement

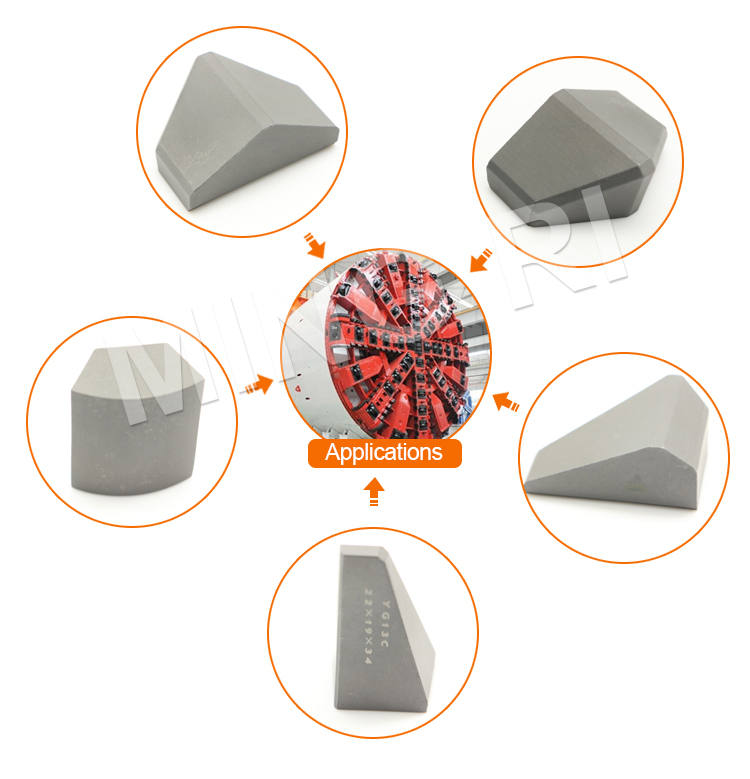

Application of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

Carbide shield cutter normally used for

coring softer rock formations,

overburden drilling,

and cleaning of drill holes

Production Process of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

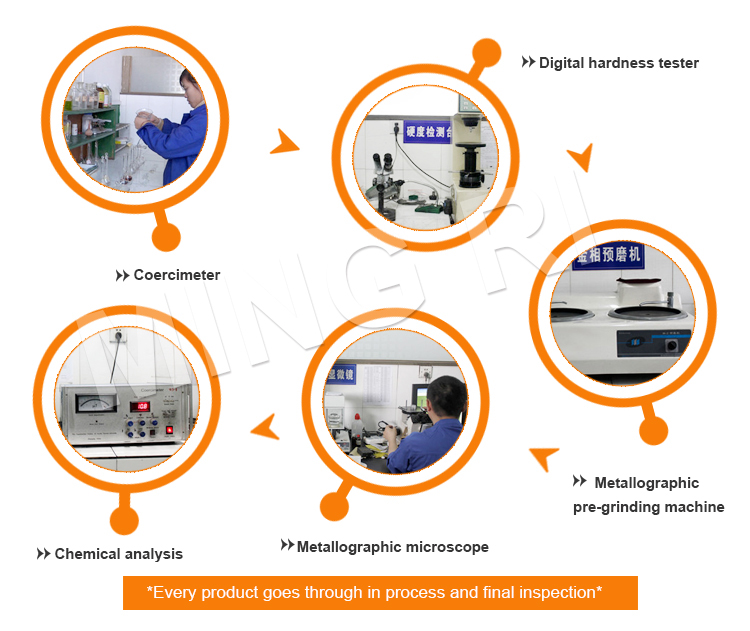

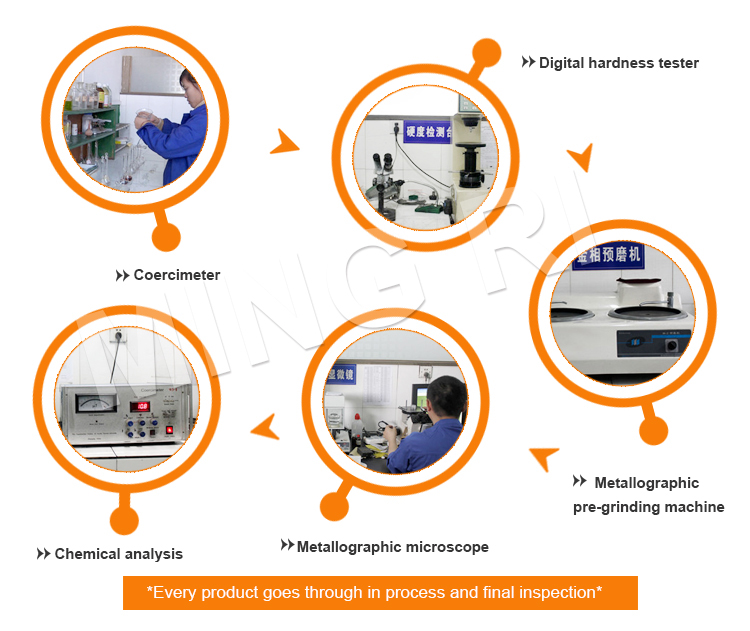

Test process of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

1st,Mass production,press the raw materials to shape blanks,

Notes:all carbide shield cutter blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide shield cutter clean and nice surface.

Packing of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

step 1, wrapped carbide shield cutter in paper to avoid carbide shield cutter TBM be broken

step 2, put the carbide shield cutter in inner small carton box

step 3, put the inner box into outter carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

Description of hard alloy shield cutter teeth

Description of hard alloy shield cutter teeth

hard alloy shield cutter teeth for Tunnel Boring Machinery Tool Part

-100% virgin raw materials, stable chemical properties, long life circle.

-High hardness, good hardness, excellent wear-resistance.

-High accuracy with long lifespan

-Hip sintered, good performance

-Various sizes and full types available

-Products can be customized upon requirement

Application of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

Carbide shield cutter normally used for

coring softer rock formations,

overburden drilling,

and cleaning of drill holes

Production Process of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

Test process of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

1st,Mass production,press the raw materials to shape blanks,

Notes:all carbide shield cutter blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide shield cutter clean and nice surface.

Packing of Zhuzhou Mingri manufacturer carbide TBM tip carbide shield cutter

step 1, wrapped carbide shield cutter in paper to avoid carbide shield cutter TBM be broken

step 2, put the carbide shield cutter in inner small carton box

step 3, put the inner box into outter carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn