Standard parts

All categories

Blades serious

All categories

All categories

1/1

Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

Product serial number

00010

Category

Carbide button

Quantity

-

+

1

description

Product Description

Description of Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

-100% virgin raw materials, stable chemical properties, long life circle.

-High hardness, good hardness, excellent wear-resistance.

-Various sizes and full types available

-Products can be customized upon requirement

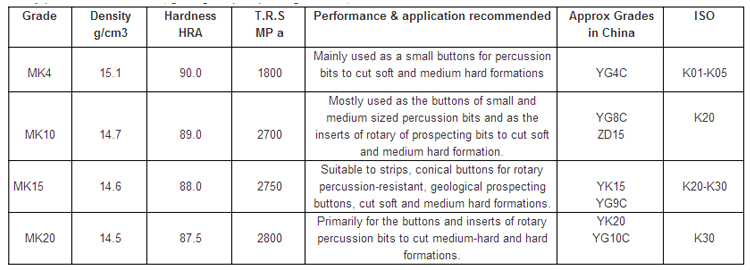

Grade of Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

Mainly used as small buttons for percussion bits to cut soft and medium hard formations, small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations.

Other grades as customer's requirement

Drawing of Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

1,when buyer send product size, we can provide drawing.

2,When send sample to us, we can provide drawing.

3,When give us picture of product, we can provide drawing.

Product Uses

Application of Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

Carbide button teeth normally used for

Grinding cement clinker,

Grinding cement limestone

Grinding cement bauxite, iron ore, etc

Production Process of Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

To ensure the quality and the requirements of the drawings can be met before mass production

1st:, Start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

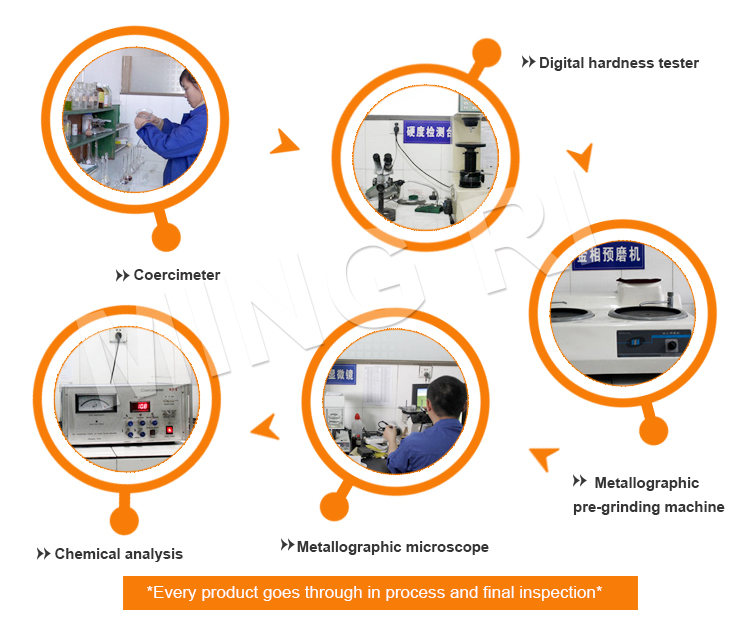

Test process of Hard alloy oil field drill bits cemented tungsten carbide button teeth tips

1st,Mass production, press the raw materials to shape blanks,

Notes: all carbide button blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2 set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide button clean and nice surface.

Packaging & shipping

Scan the QR code to read on your phone

Page rights reserved:Zhuzhou Mingri Cemented Carbide Co. IPv6 supported 湘ICP备10204182号-1 www.300.cn